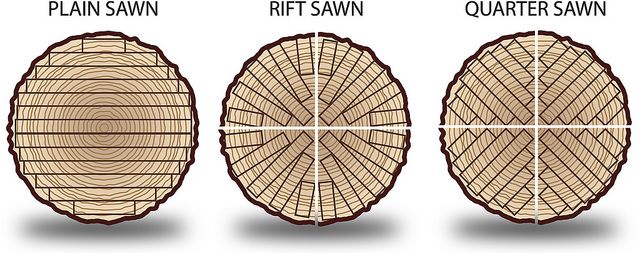

The angle at which a board is cut determines how the finished product looks. Wood flooring is typically cut on one of three ways: plainsawn, quartersawn or riftsawn.

Plainsawn

Plainsawn is the most common and least expensive method of wood flooring cuts. Plainsawn contains more variation than the other two cuts because grain patterns resulting from the growth rings are more obvious. This is the most economical method because it creates the widest boards with the least amount of waste. Plainsawn is less dimensionally stable.

The flooring will tend to expand and contract more across the width of the boards.

Quartersawn

Quartersawing produces less board feet per log than plainsawing and is therefore is more expensive. The log is first cut into quarters and then sawn perpendicular to the growth rings. Quartersawn wood twists and cups less, wears more evenly and is more stable. When quartersawn flooring is introduced to changing climates and humidity, the wood expands and contracts vertically instead of horizontal.

Quartersawn flooring is a most ideal choice for installations over radiant floor heating, as recommended by the National Wood Flooring Association.

Riftsawn

Riftsawn is similar to quartersawn, but the cut is made at a slightly different angle.